For safe and secure delivery.

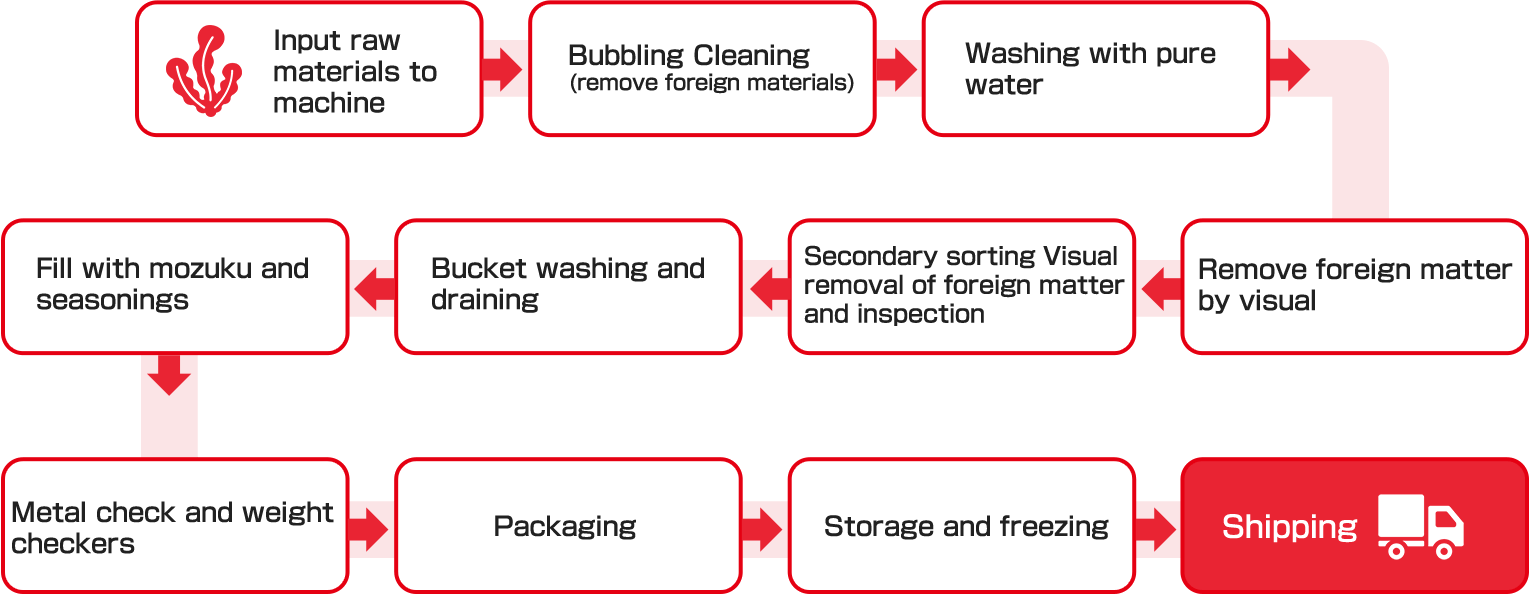

PRODUCTION

Sea vegetable is shing when freshly brought in for production, yet as this is an all-natural product, sometimes small sea creatures, stones, or shells are mixed with sea vegetable.

The sorting process to remove them cannot be automated, and requires a patient and meticulous “human” touch.

On the other hand, the production line, which boasts one of the highest production volumes in Japan, and our proprietary equipment and in-house developed manufacturing machines are playing an active role.

We continue to send delicious sea vegetable products today from the one and only line that is packed with the idea and technology of “creation” policy.

The main factory, located next to the head office, has succeeded in achieving a very high level of automation, from manufacturing to boxing. However, no matter how much mechanization has progressed, the mainstay of the manufacturing site is still the power of “human resources Workers talent” that combine skilled techniques and motivation.

While the latest machines and new technology, equipment are being introduced on the production line, a large number of staff of over 300 people are still working hard in each section.

Even for Still in salted and dried products, the delicate senses of the human eye and fingertips are indispensable in identifying and removing of foreign matter. We are not thinking of leaving this sorting work to the machine.

We always stand in the customer’s shoes, and our strong desire not to overlook even the smallest foreign matter enables us to maintain our sense of responsibility.

In addition, we have also completed an employee education system that allows individuals to grow on their own.

It can be said that the reason why the ingenuity to motivate employees, such as the unique award system of gold, silver and copper for excellent employees, has been successful.

We can operate and improve production equipment efficiently because we have excellent “human resources”.

We are actively introducing advanced technologies not only in the production line but also in the peripheral facilities surrounding the line, such as original equipment (filling machines, weighing machines, packaging machines, etc.) developed jointly with machine manufacturers and automatic warehouses.We are also focusing on thorough hygiene management. We have also established traceability to understand the production, manufacturing, and distribution channels of products.

We have established a production system that makes the best use of the power of people and technology. It is a great feature that cannot be imitated by other companies, and it is a property.

No matter how much mechanization advances, the main role of the manufacturing site is still runned by “human power” that combines skilled techniques and motivation.

Through many processes, we deliver safe and secure products to customers’ tables.

QUALITY CONTROL

Our quality control department has a plenty of missions.

Important tests such as microbiological and physicochemical tests are part of our daily work. Among the various roles such as hygiene management of business production lines and work environment, quality control that focuses on the “customer’s point of view” is the most important mission.

Here we introduce the current status of our quality control system, which manages hygiene and management from the customer’s perspective and supports the creation of safe and secure products.

Here we introduce the current status of our quality control system, which manages hygiene and management from the customer’s perspective and supports the creation of safe and secure products.

In Japan, where sea vegetable is the most widely eaten in the world, we are proud to be a company that is more passionately challenging the potential of sea vegetable than any other.

We have a sense of mission to provide our customers with safe and delicious sea vegetable products. It is a source of energy that drives quality control staff.

The basis of this is the strict control of the raw material procurement stage. It consists of various inspection work at the manufacturing stage and fine quality control work that includes hygiene management.

At the raw material procurement stage, we carry out hygiene surveys of fisheries companies and contract factories that purchase raw materials in cooperation with the manufacturing department.

Business trips to Hokkaido and Okinawa are a daily occurrence.

In general, many companies mainly perform sampling inspections after manufacturing and before shipping. Of course, we do such inspections, but we also thoroughly inspect each part at the “entrance” in the manufacturing process, such as inspections at the time of receiving raw materials and physics and chemistry inspections at the pre-manufacturing stage.

We are constantly striving to ensure safety at a higher level.

The quality control room in the head office factory is equipped with precision inspection equipment such as high performance liquid chromatography in preparation for advanced inspection work. We also take a leadership role in ensuring that each and every employee at the manufacturing site is in charge of hygiene management.

| Raw material control | Microbiological inspection and quality confirmation inspection at the time of receipt and use. |

|---|---|

| Product control | 1.Physical and chemical inspection by liquid chromatography (HPLC), pH meter, Brix meter, etc. for each manufacturing lot, etc. at the time of manufacturing. 2.Microbiological inspection of each production lot after production, keep sample retention. |

| Manufacturing process and equipment control | Sampling and wipe inspections by process and equipment. |

| Control of additives, drugs, etc. | Control of quantity and prevention of misuse. |

| Employee management | Education and guidance on hygiene, etc. |

| Shelf life control | Shelf life inspection for setting shelf life. |

| Document management and preparation | Product specifications, labeling checks, etc. |

RELIABLE

SUPPLY

Sea Vegetable has been attracting a lot of attention for its health and diet benefits, and we are the nation’s leading supplier of sea vegetable.

We handle all kinds of sea vegetables from popular colored sea vegetable to rare species.

We also develop and manufacture salted and dried products, private brand products for supermarkets and convenience stores, and original products developed in-house. We are able to meet not only domestic needs but also overseas needs because we are a pioneer in the sea vegetable industry.

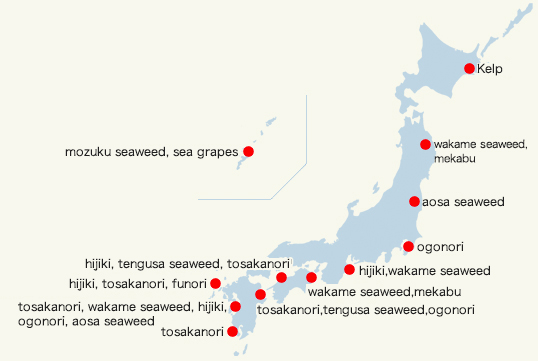

We have established a system that enables us to reliably procure the required products from more than 1,000 customers in Japan, from Hokkaido to Okinawa, as well as all over the world.

In general, most trading companies and manufacturers specialize in one or two or three sea vegetable products, such as wakame or hijiki, but we are one of the few comprehensive manufacturers in Japan that handle all kinds of sea vegetable products.

This wide range of product capabilities is supported by a network of about 200 domestic and international suppliers.

It is not unusual for us to participate directly in the bidding of fishing federations throughout Japan.

For example, we purchase the finest kelp from a middleman in Kushiro, Hokkaido, and procure selected mozuku and sea grapes from a fisheries company in Okinawa.

We also procure wakame from Sanriku, Ise Bay, and Naruto, and Tosakanori (sea vegetable) from all over western Japan, carefully selecting the best seasonal ingredients.

Similarly, we have suppliers in Kumamoto, Mie, and Fukushima for Aosa, and our great strength is that we have suppliers in various regions for the same items.

By keeping a close eye on market price changes and seasonal trends, we are able to deliver the highest quality and most reasonably priced merchandise at that time of the year.

In addition to procurement from all over Japan, we are also expanding our procurement network overseas for some sea vegetables that are difficult to procure domestically.

Examples include Canada’s Primula canadensis and Chile’s Suginori. We have also secured procurement routes to neighboring Asian countries to prepare for possible shortages.

Major suppliers locations: excerpts

HEAT

STERILIZATION

METHOD

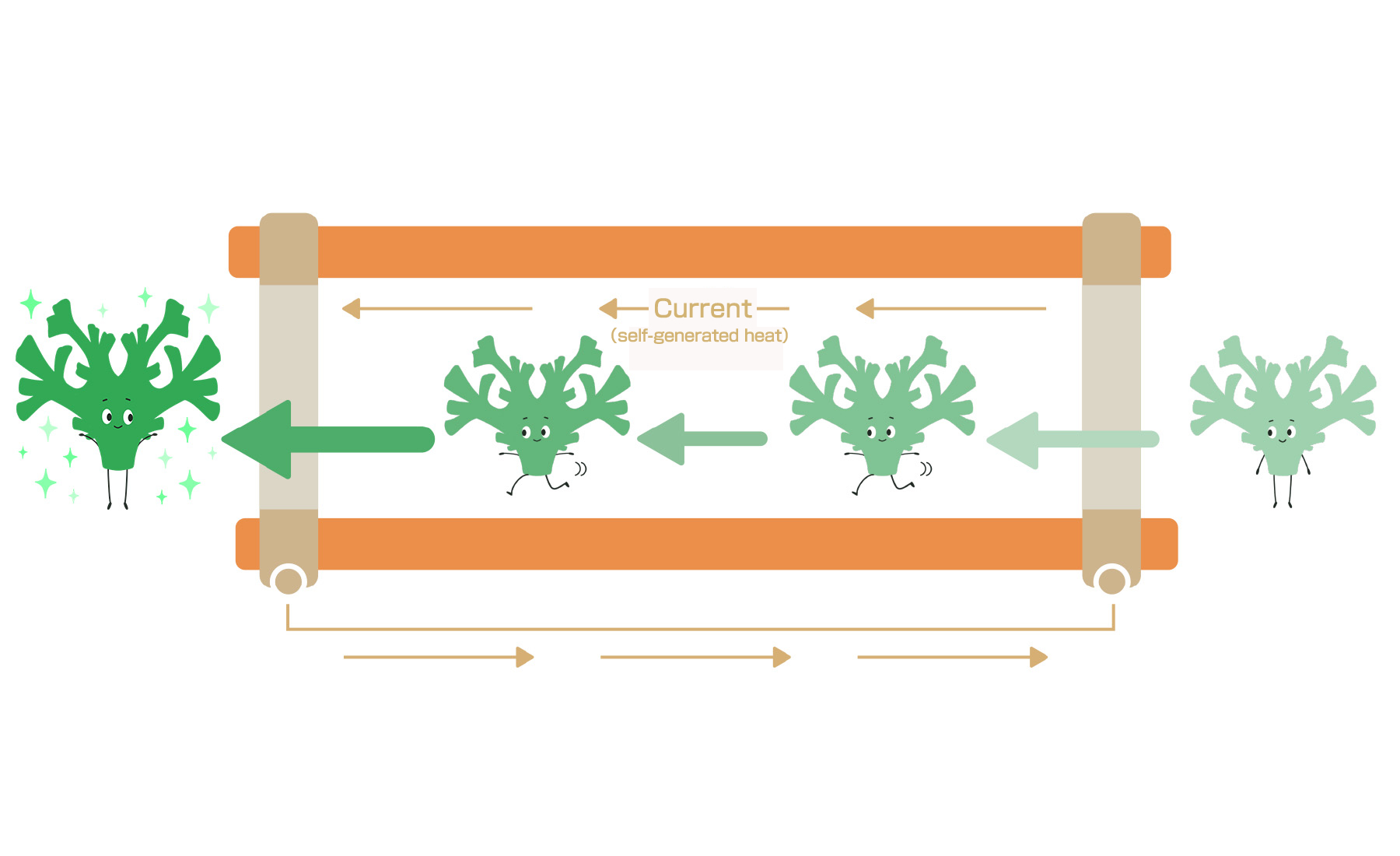

The secret behind the delicious texture of Kaneryo is the heating and sterilization method using THC (TAKAKI Heating and Cooling Machine)!

A stainless steel plate is attached to the device as an electrode, and when sea vegetable is placed in the device and electricity is passed through it, the sea vegetable becomes a conductor and self-heats, allowing it to be heated in a short period of time.

The heating time is greatly reduced compared to fire or steam by passing electricity.

Sterilization of raw sea vegetable without losing its texture is now possible.

| Kaneryo’s THC (TAKAKI Type Heating and Cooling Machine) | Conventional steam machines | |

|---|---|---|

| Formula | The turnip itself is heated by electric resistance and sterilized by heating the turnip directly through electricity. | Mekabu is moistened with water, and then heated and sterilized by indirect heating with steam from the mekabu and water. |

| Sterilization | Direct energization allows electricity to flow throughout the body, enabling uniform heating by self-heating. Fast response speed because the temperature control directly controls electricity. This allows continuous sterilization at a stable temperature. | Uniform heating is impossible due to uneven solid temperatures caused by indirect heating. |

| Qualilty | “Since the entire solid is energized and self-heats, uniform and rapid heating is possible, which reduces the burden on the solid. This enables production with minimal deterioration in the color, flavor, texture, and other qualities of the solid itself.” |

“Indirect heating by steam causes significant damage to solids because the temperature rises in the order of water, solid exterior, and solid center. There is a problem that components of solids (such as umami nourishment) are drained out in draining after heating in order to adjust the amount of water required for heating.” |

| Manufacturing Environment and Other Information | “Know-how is required to provide stable heating for raw material pretreatment. No fossil fuels, etc. are used and earth-friendly fuels (electricity) are used.” |

Temperature control can be easily achieved, but the hygiene and noise associated with rising temperatures in the operation can be distracting. |